Mixing System

Product Model:

DO36

Product Details

principle

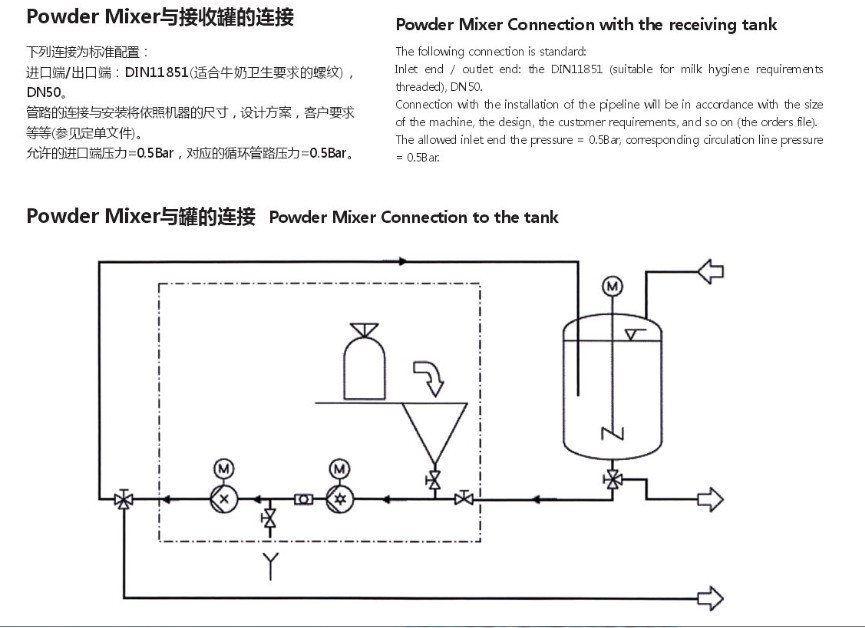

Powder Mixer mainly consists of two parts:

1. One comes from a self-priming centrifugal pump.

2. The other is the shear mixing pump, which acts as a built-in rotary homogenizer.

The self-priming pump sucks the base liquid from the receiving tank, and then sends it to the mixing pump through a short pipe. When the butterfly valve at the suction end of the self-priming pump is gradually closed, a strong vacuum (about 0.5Bar) will be generated between the pump and the butterfly valve. At this point the material will be sucked from the hopper. Powders or liquids are drawn directly into the liquid stream under the action of vacuum suction. This mixture is first sent to a self-priming pump for preliminary mixing. These premixes are then pumped to a shear mixer pump, where the under-dissolved material is completely sheared and mixed at a line speed of up to 30m/s and a shear tolerance of 0.3mm.

Powder Mixer mixing systems are commonly used to mix, dissolve, and deliver powdered and granular materials with liquids (such as sugar, milk powder, cocoa powder, thickeners, oils, liquid seasonings, etc.) into a receiving tank.

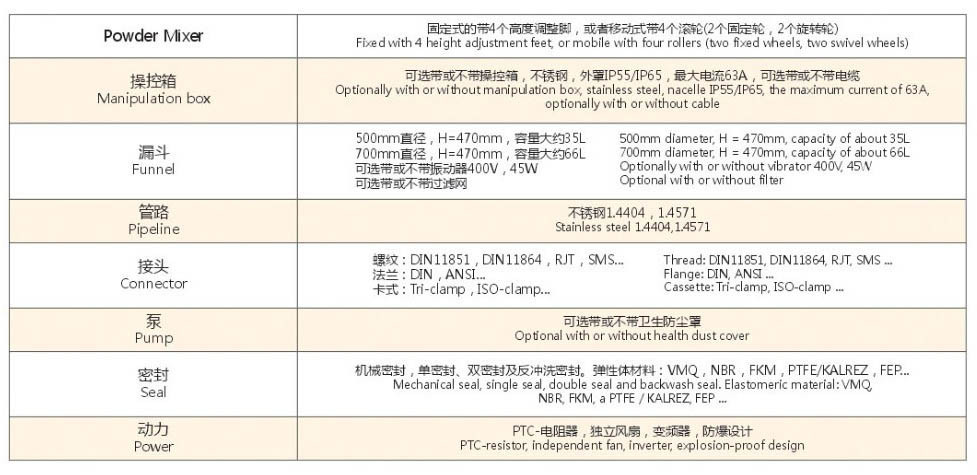

Configuration Options