Aseptic Tank

Product Model:

DO43

Product Details

Purpose of the device

As the name suggests, a sterile tank is a storage tank that maintains a sterile environment. It is installed in the middle of the ultra-high temperature aseptic canning machine and plays the role of buffering.

Structure

1. It can avoid the backflow of the products of the ultra-high temperature sterilizer, and the products with more sterilizers than canning machines can be temporarily stored in aseptic tanks to ensure product quality.

2. When the filling machine fails or is suspended, the sterilizer can work normally, and the product is stored in the aseptic tank.

3. When the ultra-high temperature sterilizer fails or is suspended, the products stored in the aseptic tank are provided to the canning machine, and the canning machine works normally to improve production efficiency.

4. The system uses PLC automatic control, and Siemens man-machine interface realizes convenient whole-process monitoring and man-machine dialogue operation.

5. Design the canned volume according to customer needs.

Purpose of the device

As the name suggests, a sterile tank is a storage tank that maintains a sterile environment. It is installed in the middle of the ultra-high temperature aseptic filling machine and acts as a buffer.

Structure

1. It can avoid the backflow of the products of the ultra-high temperature sterilizer, and the products with more sterilizers than canning machines can be temporarily stored in aseptic tanks to ensure product quality.

2. When the filling machine fails or is suspended, the sterilizer can work normally, and the product is stored in the aseptic tank.

3. When the ultra-high temperature sterilizer fails or is suspended, the products stored in the aseptic tank are provided to the canning machine, and the canning machine works normally to improve production efficiency.

4. The system uses PLC automatic control, and Siemens man-machine interface realizes convenient whole-process monitoring and man-machine dialogue operation.

5. Design canned stars according to customer needs.

With the development of dairy and juice industries, more and more customers have adopted UHT sterilization and aseptic canning to produce dairy and juice. If there is an aseptic canning machine directly behind the UHT ultra-high temperature sterilizer, since the production flow of UHT should be larger than that of the canning machine, some products need to be backflowed. Repeated sterilization, product quality will be seriously affected, and even cause waste. Therefore, if an aseptic tank system is added between the sterilizer and the canner, the above problems will be solved. At the same time, improve production efficiency, ensure product quality, reduce material waste, and reduce production costs.

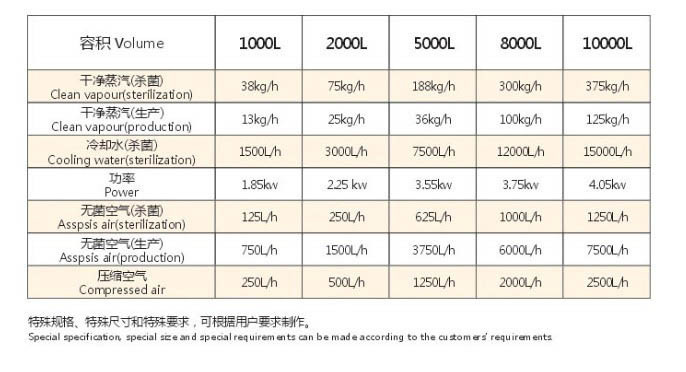

Technical Parameters